In 2019, Botanican partnered with Verve Dynamics Lesotho, who operate a world-class cannabis processing plant in Bela-Bela, Lesotho. Verve Dynamics is led by Richard Davies, an extremely talented and respected alchemist and innovator. A forward-thinking pioneer in the field of afro-botanical extracts, Richard is the visionary behind the processing operation in Lesotho. He works closely with Botanican at every stage of the design, development, manufacturing, and testing of our products.

PROCESSING

Making our CBDA products

Cold ethanol extraction

Verve Dynamics utilises a cold ethanol extraction technique to preserve as much CBDA as possible, and extract the full spectrum of cannabinoids and terpenes. Few companies in the world have managed to stabilise CBDA which makes Botanican’s CBDA products truly exceptional.

Making our oils

After extraction, the distillate is combined with organic olive oil to make Botanican's CBDA oil products.

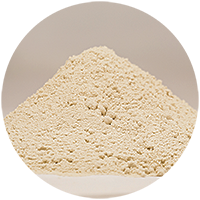

The powder for our capsules

Verve Dynamics transforms our full spectrum extract into CBDA powder, while still maintaining the cannabinoid and terpene profile of the plant. The result is combined with tapioca powder and made into capsules.

CERTIFICATION

Testing with 3rd party labs

Botanican's products are regularly tested by independent laboratories throughout the cultivation and manufacturing process. We test the soil, water, and plant material (flower and leaves) at every stage. Each product batch is tested by Verve Dynamics, as well as independent, third-party laboratories.

NEWSLETTER SIGNUP

Stay up to date with Botanican

Join our mailing list for latest news and updates, and to learn how we are improving lives all over the world.